- Home

- Faculty Members

- Department of Mechanical Engineering

- Takeshi Nishioka

Faculty of Engineering

Department of Mechanical Engineering

- Key words

- Tribology, friction, wear, lubrication, abrasive, polishing, erosion, micro slurry-jet erosion, MSE, chemical mechanical polishing, CMP

Doctor of Engineering / Professor

Takeshi Nishioka

Education

Department of Aeronautics, Faculty of Engineering, University of Tokyo

Master Program, Graduate School of Engineering, University of Tokyo

Doctor Program, Graduate School of Engineering, Tohoku University

Professional Background

Chief Specialist, Center for Semiconductor Research & Development, Toshiba Corporation

Senior Research Scientist, Corporate R&D Center, Toshiba Corporation

Visiting Scholar, School of Engineering, Vanderbilt University

Consultations, Lectures, and Collaborative Research Themes

Consultations and collaborations on friction, wear, lubrication and polishing process

Lectures on mechanical engineering in semiconductor process developments

Main research themes and their characteristics

「Hydrodynamic Effects of Pad Surface Roughness in CMP Process」

It is important to estimate how large the hydrodynamic pressure of slurry is, for understanding the mechanisms of planarization process, because it effects the decrease of contacts between wafers, pads and abrasives. In conventional chemical mechanical polishing (CMP) process, polishing pads with several tens of micro meters of surface roughness are widely used. The roughness is considered as important factor for effective and uniform distribution of slurry, and should be a dominant parameter of the slurry film topography.

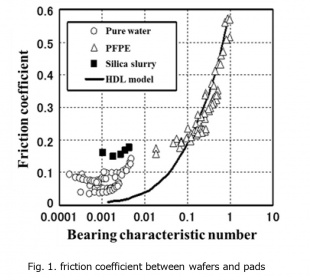

Three-dimensional sinusoidal roughness model is proposed for the hydrodynamic pressure evaluation of slurry in CMP process. The model includes several assumptions of cyclic roughness, no pad deformation and so on. The measurements of the friction coefficients between the wafers and the polishing pads show good agreement with the model. Figure 1 shows the small hydrodynamic effects in the conventional CMP conditions, i.e. high pressure, low relative speed and low viscosity of slurry, however, the possibility of controlling the slurry film thickness by hydrodynamic effect with large bearing characteristic number, i.e. high viscosity, high speed and low pressure conditions, for better planarization. The model should be useful for the estimation of hydrodynamic effects of slurry and the understanding of the contact mechanism between the wafers, the pad and the abrasives in CMP process.

「Effect of slurry pH on the micro slurry-jet erosion of SiO<sub>2</sub> film」

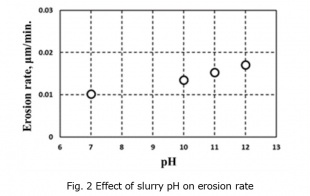

Recently, micro slurry-jet erosion (MSE) test was proposed to the evaluation of the mechanical properties of the hard surfaces. MSE is also expected to be applied to the microfabrication like other abrasive technology. Chemical mechanical polishing has been one of the key processes in semiconductor production. It uses both of the mechanical and the chemical effects of slurry in order to establish the precise and small damage surfaces. In this study, the effect of the slurry pH on MSE rates were investigated. SiO<sub>2</sub> film was selected as the processed material, which is widely used as the dielectric layer in semiconductor devices.

Figure 1 shows the effect of slurry pH on the erosion rate. It increases as the slurry pH increases. This property shows the similarity to the dissolution rate and the polishing rates of SiO<sub>2</sub>. Decrease of Si-O bonding strength should be considered as the mechanism of these rate increases. This result shows the chemical effects of slurry can be a control parameter of MSE process.

Major academic publications

T. Nishioka, K. Sekine, and Y. Tateyama

“Modeling on Hydrodynamic Effects of Pad Surface Roughness in CMP Process”

Proc. of International Interconnect Technology Conf., IEEE 89 (1999)

T. Nishioka, S. Iwami, T. Kawakami, Y. Tateyama, H. Ohtani and N. Miyashita

“Modeling on Mechanical Properties of Polishing Pads in CMP Process”

Material Research Society Symposium 613, E1.5.1 (2000)

T. Nishioka, H. Yano, G. Minamihaba, D. Fukushima and S. Seta

“Extendibility of CMP Process to Cu/Low-k Interconnect Fabrications”

Proc 11th International Conf. on CMP Planarization, 4E (2006)