- Home

- Faculty Members

- Department of Electrical and Electronic Engineering

- Kazushige Nakao

Faculty of Engineering

Department of Electrical and Electronic Engineering

- Key words

- Electromagnetic induction, Induction heating, Power contactless transmission, Thermal management

Doctor of Engineering / Professor

Kazushige Nakao

Education

Osaka Prefecture University Graduate School of Engineering (Bachelor's ,Master's Program)

Osaka University Graduate School of Engineering Science(Doctor Program),

Kobe University Graduate School of Business Administration(MBA)

Professional Background

Mitsubishi Electric Corporation Advanced Technology R&D Center, Group manager/

Technical Achievement Award of the Heat Transfer Society of Japan(2006), Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology(2010)/

Chairperson of Investigating R&D Committee of IEEJ

Consultations, Lectures, and Collaborative Research Themes

Induction heating system, Power contactless transmission system,

Thermal management for power electronics system et al.

Main research themes and their characteristics

「Applied Research to Industrial Heating Process of Induction Heating Mixing Impeller」

In industrial mixing process with heating, heat transfer is performed normally through vessel wall and/or internal coil surface heated by heat medium, so the overall heat transfer coefficient is not large. Newly developed Induction heating mixing impeller(IHMI) has bigger heat transfer characteristics than conventional heating method because of rotating and heating by Induction heating. As a result, this IHMI can be expected to have better heat transfer and higher heat response.

We investigated fundamental thermal characteristics of a newly developed IHMI. Using water and 60wt%, 80wt% glycerol solutions, we conducted an experiment on heat transfer between blade and liquid and have obtained the following conclusions.

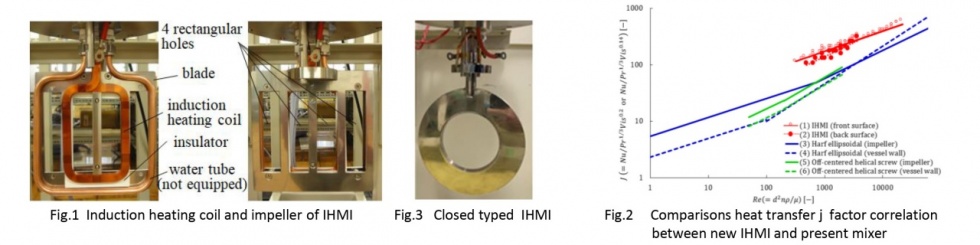

Fig.1 shows the pictures of induction heating coil and blade. The blade made of two stainless steel plates has the dimensions of 150 mm B×150 mm H×14 mm T. The induction heating coil made of copper has 5 turns along the direction of thickness. IH coil was sandwiched between two blades through insulator and half closed. Fig.3 shows closed typed IHMI.

Fig.2 shows the correlations proposed for heat transfer coefficient between solution and vessel wall in terms of j-factor. Heat transfer coefficient h between blade and liquid has been calculated with W=hAΔT (W: heat transfer rate, A:surface area, ΔT: temperature difference between average impeller temperature and solution temperature)and correlated by next equation(1).

<strong>Nu = h d/k = 4.13Re0.53Pr1/3Vis−0.14 for 4.9×102 < Re < 5.4×104・・・・・(1)</strong>

Also, j-factor of IHMI is 2.0 more times as much as that of vessel wall. The time variation of ΔT was well approximated by a primary delay system. Its time constant is 6 – 25 s , its value is about 1/10 times as the conventional type and is proportional to 1/h.

「Research for advancing high power density of high Frequency Transformer」

Solid state transformer(SST) has been focused as a power conversion system. SST can insulate and transform voltage by utilizing a high frequency transformer which have merits to minimalize its size. This is adapted for electric train in Europe, and its research and development has been accelerated not only for future train but also airplane and offshore wind power generation system around the world, especially in Europe and USA.As a target of R & D, high power density ratio(power/volume: W/m3) is required.

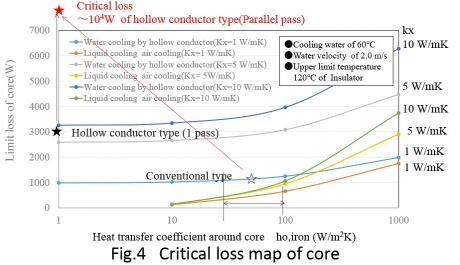

We made a prototype of water cooled typed 7kw,3kHz.The loss and surface temperature with optical fiber under the electro magnetic field is measured. Also, from thermal fluid analysis, we found that the critical loss of water cooling with hollow conductor is bigger about 10 times than air cooling type or oil inversed cooling type(Fig.4).

Major academic publications

Nakao, K., E.Ozaki, T.Yumikura, M.Ikeuchi , G.Yamanaka and Y.Hirata; “Analogy-based Evaluation of Heat and Mass transfer Characteristics in a Falling Liquid Film along a Vertical Absorber with Spirally Fir-finned Tube,” Kagaku Kogaku Ronbunshu, 32,48-58(2006)

Takehara H., Hirata Y, Ohmura N., Noriyuki N., Nakao N. and Nakao.K; “Heat Transfer Characteristics of Induction Heating Mixing Impeller,” MIXING16 16th European Conference on Mixing (2018)

K. Nakao, “System integration technology advancing higher power density for future power converter ”, The journal of the Institute of Electrical Engineers of Japan, vol.140, No.7,412-415,428-431 (2020)